The materials that make up the things we use every day often get overlooked as simply parts of a whole. But for nature lovers and adventure seekers specifically, who care deeply about the environment, it may come as a surprise that the products and gear they use while enjoying the outdoors can actually be harmful to the planet.

Take petroleum, for example, a fossil fuel, is a key component of many materials often used in the production of outdoor recreation equipment. Moving away from petroleum and choosing more planet friendly materials, such as new microalgae made materials, can help the outdoor recreation industry mitigate its impact.

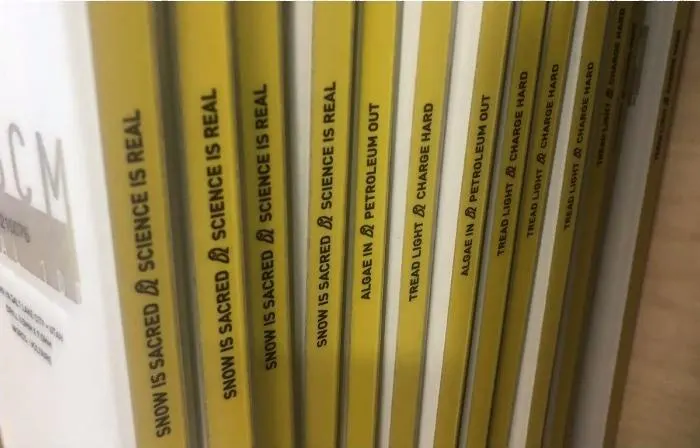

That’s where Checkerspot comes in. The company created the brand WNDR Alpine to animate what is possible with these sustainably sourced materials. Rather than using traditional, petroleum-based ski layup materials like ABS plastics, WNDR Alpine is using their AlgalTech technology in their skis allowing them to manufacture in a more sustainable way that actually results in higher performing equipment. Now it is broadening applications for the material beyond skis.

“With our AlgalTech materials in our backcountry skis, we’re targeting lighter weight, bringing more strength-to-weight, and improving durability,” Charles Dimmler said. “Those are properties sought after in the automotive industry and in the aerospace sector for fuel efficiency, and elsewhere.”

I spoke with Dimmler, Checkerspot CEO and co-founder, as part of my research of purpose-driven businesses, to learn more about AlgalTech, and to see where the company is headed with its innovative materials.

Christopher Marquis: Tell me about AlgalTech. What is it and how is it made?

Charles Dimmler: The most direct answer is it’s a portfolio of ski specific materials under the WNDR Alpine brand that has high bio-based and algal-based content. One AlgalTech material is a urethane composite that we're engineering into the core of the skis called Algal Core. Ordinarily in construction, you wouldn't be able to see it because it's buried inside the skis, except we created a little window on the top sheet so you could actually see through to it. The other is definitely visible, which is a cast urethane that's on the side wall called Algal Wall. This side wall is the part of the ski that sits above the edge just beneath the top sheet on both sides. It protects the Algal Core inside. The algal-based content of the Algal Wall is over 60 percent. These materials help with the skis performance and durability. So that's the most direct answer to what is AlgalTech.

That's where we've started. But there are other things that we're working on, other parts of the skis, other materials beyond urethane. And from my standpoint, that’s what I'm really energized about because we can utilize biology to effectively accelerate getting to oils, often referred to as triglycerides, that have unique chemistries that haven't been available at commodity scale or price historically, yet these oils are available naturally because they’re produced by plants. The issue is that those plants don't fit within the agro-economic complex. They don't fit within the current distribution system. You can't grow them in the arable world. And that's what biotechnology fundamentally unlocks. We're able to utilize the genes from those plants and plug them into an expression system, microalgae, then can use it at high yield and low cost—and it scales.

That's the thing that I'm most interested in is how we can go after this whitespace of new kinds of chemistries and how the different chemistries lend themselves to performance properties based on the physical properties of the materials. So we've just gotten started bringing to life what's possible through these first applications.

Marquis: Why do you think it is important to create innovative materials like AlgalTech that are more environmentally friendly?

Dimmler: Our collective experience throughout the pandemic has amplified the importance of science and how real and threatening climate change is. The thing that alarms me is we didn't nail it with the pandemic, in my opinion. I think most people agree with that, though. When you look at something like climate change, even from a policy perspective, surely people can wrap their heads around how this can be a driver for economic development. Wherever you sit on the spectrum, it’s clear we need to do something to rise to the challenge.

I draw a lot on history. And when you look back at 20th Century American history and the World War II era, there was a calling. Everybody pitched in, whether that was through recycling programs or women going into factories. I feel like we need to come together societally to lock arms and pitch in and do our part. We’re not overt about it through our business, but what we're trying to bring to life with WNDR Alpine is creating a community of people that are pitching in. It happens to be in a category with outdoor recreation where, generally speaking, people care a lot about the environment, but we need to get beyond just that segment and promote the idea that we need to come together. And when we do, we can do something incredible.

Marquis: What are some other potential applications for AlgalTech?

Dimmler: Since last year, as we’ve grown and raised some more capital, we’ve been using the proceeds to do a couple of things. One is utilizing the same base monomers in our AlgalTech, the same oils, to grow into other categories that contain more functional ingredients—categories like food, nutrition, and personal care as examples.

More specifically with materials themselves, a lot of folks sometimes view what we're doing with our brand WNDR Alpine, skis, and outdoor recreation as defining the company. They see Checkerspot as a ski company, but that's actually not all what we are. With our AlgalTech™ materials, we’re targeting properties sought after in the automotive industry, in the aerospace sector for fuel efficiency, and elsewhere. So that's the other thing that we're working to bridge into. Also within materials, we announced a partnership with Gore, and now we're working on things like performance textiles and the single most significant challenge that the outdoor recreation industry is trying to solve: moving away from what are called perfluorinated compounds (PFCs) that negatively affect people and the planet.

Marquis: Speaking of partnerships, do you share your innovative materials with other companies or organizations?

Dimmler: So the short answer is yes, we are making the technology available to others. We have an existing partnership with a Japanese chemical company called DIC. We talked about Gore. There's a company called Beyond Surface Technologies that we've been supplying algal oil to that is commercializing a moisture wicking finish. So those are some early examples now. Because of the profile of WNDR Alpine, there's a lot of inbound interest in both accessing materials that we're selling and also to access our platform itself. And we can't do all of that ourselves, so we'll announce more licensing soon to get the technology out there.

We are also testing out a pilot program where we work with a smattering of designers and product developers in a project to enable them with materials to say like, “Hey, what might you innovate? What might you come up with?” The analogy that I would draw on is the iPhone or Android: What makes those devices so compelling? There's definitely awesome engineering and they work well, but really what draws the consumer in are the apps. And the apps weren’t created all by Google and by Apple. Apps are created by people in disparate places. We're testing this hypothesis that the same can be true in materials. There are signs and data that we've seen that we're kind of at a renaissance around economic empowerment and building things. Now people have this ability to create a product and then, in a capital efficient way, bring it to market to sell it to. You don't have to rely on wholesale and retail as the only distribution networks. So that's a pilot that we're working on in the same spirit of your question, which is democratization and enabling others to use our technology in innovative ways. So it's both partnering with big companies but also looking at how we can empower individual innovators.

We named the company Checkerspot after a butterfly that is endangered in the Sierra Nevada that's impacted by climate change. So it's not going to surprise anybody that we think climate change is real. We think that this is bigger than one company — this is a huge existential problem that a team of 40 people, like ourselves, isn't going to solve. This is huge. This is global. You've got big companies that say they care, but there's this inertia that exists with these big companies. To break through that inertia, you have to de-risk it. You have to show them what’s possible.

Our expectation isn’t that we're going to go and all of a sudden grow from outdoor recreation and start building automobiles to compete with BMW. The model is to show what's possible, but then to stay focused on innovation, and then as we demonstrate that, to make it available, to democratize it to the companies that want change but can't quite take the risk to innovate in this way, but have invested billions of dollars in supply chains, in distribution, and in connection with the consumer.